You already know which items work best for your business to start your own product line and you made an informed decision on where to sell them. (If not, make sure to read part 1 and part 2 of this series.) But what’s the best way to make the products themselves?

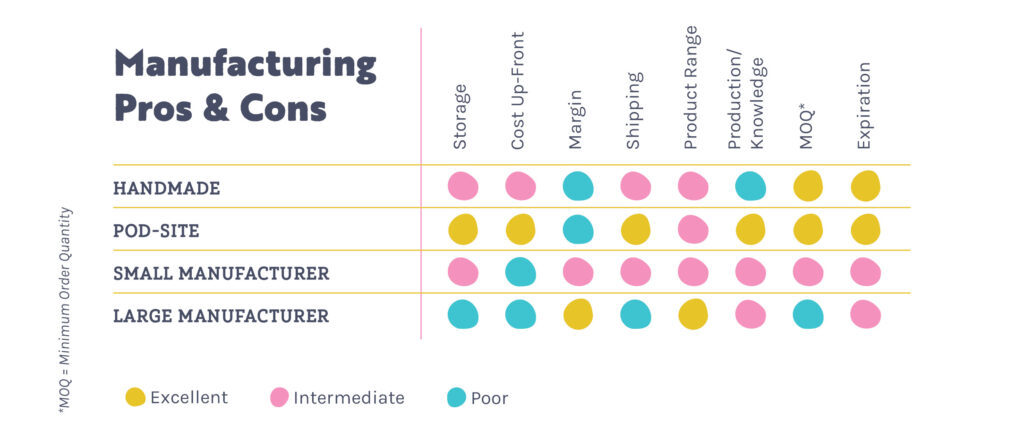

Handmade

For many small businesses, this is how they most likely start their product journey. It’s also how I started my own product line. Making my own products always felt very rewarding and my background is quite crafty. I went to a school where we could explore all kinds of materials, like metal, wood, paper, and fabric. Due to this, it felt like a natural transition from designing to making my own products.

Over time, my products looked more professional and I extended my range as well. As with everything, practice makes it better. I’m not exaggerating when I say that some of my items looked bad when I first started. But we all have to start somewhere, right? So listen to me, because I have to tell you something: When making your own products — be patient with yourself!

The best part about making your own products is that you can test new items with smaller runs. This doesn’t just work with new items though, but picking new designs for them as well. This keeps your up-front costs down, in case your audience doesn’t respond to your new merchandise as well as you hoped. It might be a great option if you intend to create products with an expiration date (e.g. calendars or designs using trending themes).

The biggest downsides of making your own products are margin and production knowledge. If you don’t know how to make an item (and also make it well), you can’t manufacture it yourself. If you have the knowledge though, you can create anything you dream up! But be sure you know about all the materials you use and the industry standards and relevant laws you have to abide by (especially for baby and children-related products!).

Your margins are on the lower side due to various reasons. One is that you most likely won’t order materials in bulk. But also, because labor is the most cost-intensive expense in making products.

You should also have enough storage space available to keep your raw materials and stock at hand. Depending on the products you decide to sell, this can be very little or quite a lot.

POD sites

POD sites can be great, especially if you are just starting with your product range journey. They can also be a valuable addition to any other manufacturing method to round off your line of products.

What’s great about them is that you don’t have to have any production knowledge yourself, the minimum order quantities start at one piece, the POD company takes care of the shipping and stores all the items, and your up-front costs stay low. But POD offers the least flexibility of all the manufacturing options. The third-party company dictates how much you can customize a product and there is no way around that. Depending on the site you use, cultivating the inventory can get quite time-consuming, especially if you use multiple sites.

Because the POD company takes care of most of the process, you will earn only a fraction of the sales price. If going down this route is worth it depends on how many sales you make and if the numbers add up for you. You have to be the judge of that.

I cover more aspects of print-on-demand sites in the blog post “Your First Surface Design Product Line: Where to Sell.”

Related Article: Developing a Product Line

and How it Helps for Art Licensing

Small manufacturer

You can collaborate with other freelancers (like sewists, laser cutters, printers, and more) or work with companies to create your product line. You could even get your products made in a welfare institution and support a charitable cause in the process.

This solution’s benefits and disadvantages are usually mid-way between making products yourself and outsourcing to a large manufacturer. If you want to stay local with your production, this could be a great way to do so. You’ll also be more flexible with changes and adjusting your product range. Your margins will likely depend on the order quantities. As you have to pay other freelancers for their time, margins could be even lower than making products yourself.

I love working with smaller, local manufacturers though for sourcing my raw materials (like printed fabrics with my own designs). Hand-making products in combination with small manufacturers might be a viable option for your business too.

Large manufacturer

If you want to go big right from the start, a large manufacturer might be a good idea for you. Especially if you plan on selling your products wholesale (more on this topic in the blog post “Your First Surface Design Product Line: Where to Sell”). I am also currently in the process of outsourcing the manufacturing of one of my best-selling items, because it gets harder for me to keep up with the demand. But getting to the desired outcome with a third-party company can be a bit of a rollercoaster, to be honest!

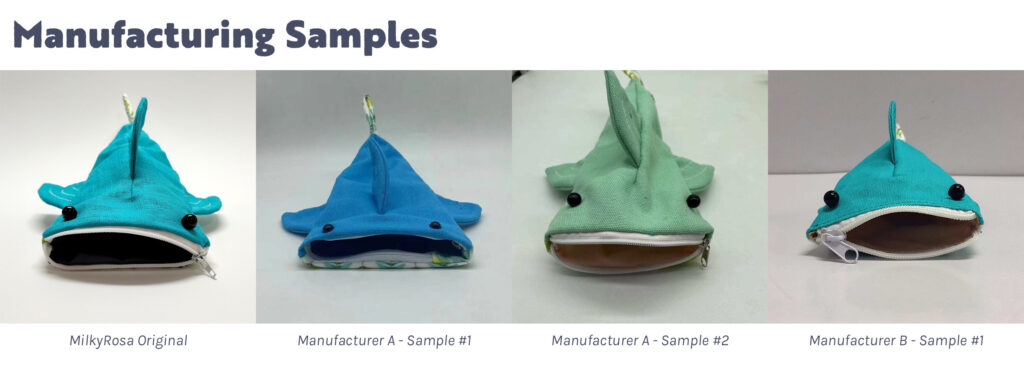

Many large manufacturers are located in Asia, which may leave you with a language barrier when communicating with them. English is used for conversations, but I felt misunderstood many times when stating my requests. So be prepared for revisions, even if you think that you explained every little detail or choice of material.

And even though you are not making the products yourself — make sure you have some basic knowledge of production. As soon as you get photos of your sample you have to be able to articulate in detail what you want to be changed (which can be a challenge if you don’t know about the production process at all).

I’d suggest contacting a few different companies and getting a sample made. This way you are able to compare the overall experience, communication, turn-around times, and quality of products. Because you might enjoy working with a company that didn’t look as good on paper and vice versa.

To me, working with a large manufacturer only makes sense if you have the storage capabilities and funds to invest in larger stock quantities. Lower minimum order quantities (below 250 pieces) are very rare. Normal MOQs could even start at 1000 pieces. But if you already have a design that sells well, this could be the option to use in the future, because you’ll get the biggest margins out of it.

I also felt it was a great benefit that I already had a product I could reference and could share photos of it with the manufacturer. I believe the process would have been much more difficult if this hadn’t been the case.

If you want to work with a manufacturer located in America or Europe you usually have to expect higher prices (and therefore lower margins). The process of even finding a manufacturer could be more time-consuming as well, because there might not be as many companies around to pick from, depending on your desired product.

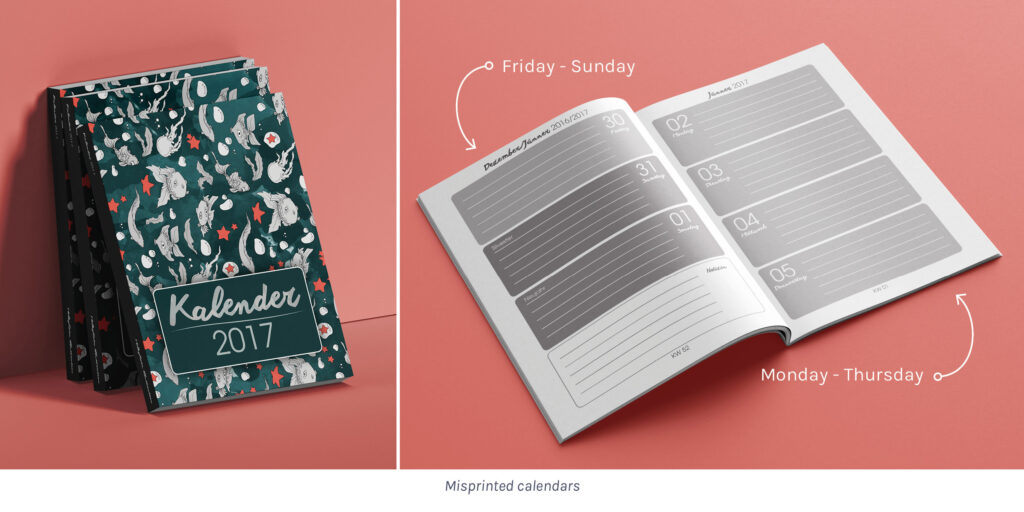

Samples

Whatever products you decide to make — invest in samples before committing to order large quantities. Whether it’s fabric, paper, or print swatches — make sure you know how the final item will turn out. Because creating your own product line is a big investment, you don’t want to order a batch of products and end up being unhappy about the finish or quality. I know ordering samples can get pricey, especially with large manufacturers. But ordering a batch of 500 pieces for $1,500 and skipping the $70–250 sample is money saved in the wrong place. Trust me. I once ordered a calendar and when I opened the box I almost started to cry. I didn’t know the print company wouldn’t print the inside of the covers. But that’s how I created the print file.

This resulted in all of my pages being pushed back by one page and all my calendar’s weeks were split and no longer on the same spread — Monday to Thursday on the right-hand side and Friday to Sunday on the left… It was my own mistake and I couldn’t sell them anymore. I’m glad I only ordered a trial run of 20 pieces, but it was still money invested I would never make back in sales.

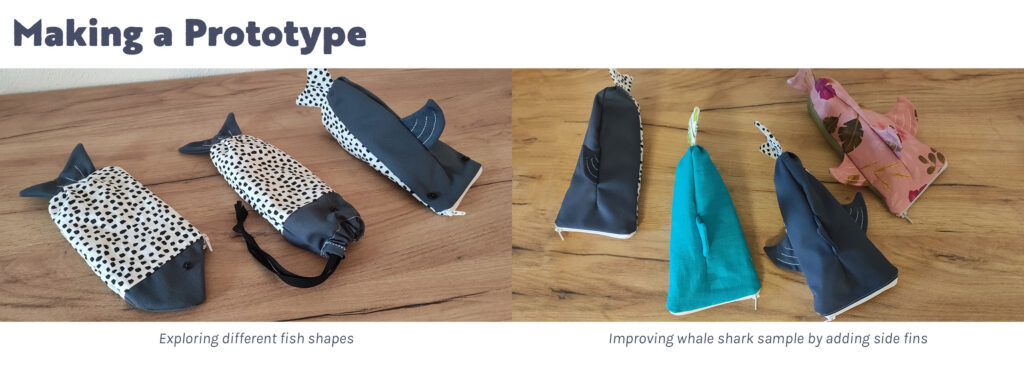

A good prototype will also help you to understand your product better, especially if it’s one you came up with yourself.

When I made my first fish pencil case I didn’t know it would end up being a whale shark. I started with a few different ideas and closing mechanisms and shapes. The mouth as the zipper was the very last option I tried out, but I fell in love with it immediately. The journey wasn’t over yet though. Making the fins is the most difficult and time-consuming part. That’s why I thought I could get away with only making two fins. I made another prototype and added both side fins. And as much as I ‘disliked’ the process of making the fins, the result was clear — I had just created a product that looked incredibly adorable and I knew it would sell really well.

I hope this series helped you to make informed decisions on how to start your own product line as a surface designer!

If you want to start your own product line as a surface designer you can read the full blog series here:

Your First Surface Design Product Line: Product Options

Your First Surface Design Product Line: Where to Sell

Written by Nina Schindlinger

Website: www.milkyrosa.com

Instagram: @milkyrosadesignagency

Class: Create Your First Product

Nina is the founder and creative director of MilkyRosa Design Agency. She specialises in branding and product design for companies that are young at heart. Her design style is bold, playful and charming, which she uses for her own line of products to make the world a fun and colourful place.

This whole series was fantastic and so helpful! Thanks Nina, for sharing your insight and expertise.